This document details the procedure for the Operation of the Air Handling Unit. It is the policy of XYZ Pharmaceuticals Limited that a written procedure shall be followed for the Operation and Cleaning of the Air Handling Unit and its use monitored to ensure smooth operation and its use monitored to obtain consistent and reproducible results minimize downtime and meet regulatory requirements.

This procedure is to be applied at the time of Operation of the Air Handling Unit

Responsibility and Accountability

Persons along with their responsibilities and accountability are

given below:

Executive – Corporate Quality Assurance

Section - In Charge

Manager - Technical

Manager - Corporate Quality Assurance

PROCEDURE

PRELIMINARY CHECK

5.1.1 Clean the apparatus externally with a clean cloth with 70% IPA.

5.1.2 Clean the unit surface, and filter with a wiping

cloth.

5.1.3 The pre-filters are cleaned once a week.

5.2 PRECAUTION

5.2.1 Switch OFF the AHU after work. Adjust the temperature to the environment of a lab. Fill the red oil in the manometer properly from time to time.

5.3 OPERATION OF AHU

Switch ON the Air Handling Unit from the main switch. The AHU in the microbiology area should be switched “ON” one hour before the start-up of the work.

5.3.3 The AHU should be given time for its establishment to attain the designed room conditions. The maintenance of temperature and RH is determined every four hours once a day by using calibrated thermometers and manometers. Check the reading on the manometer before and after switching ON the AHU.

It shows the pressure in Pascal. The pressure difference between the two locations of the microbiology section is always 5 Pa or more than 5 Pa. Calibration shall be done by an outside party.

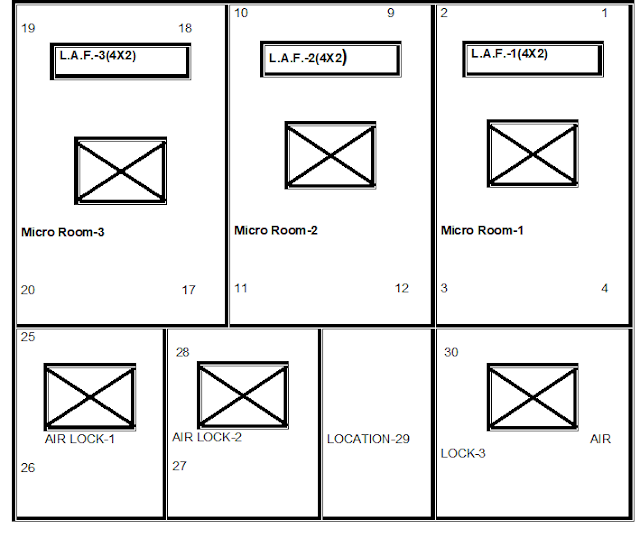

Figure 1

5.0.5 Maintain the Logbook of the Air Handling Unit on the Logbook for Air Handling Unit Appendix.5.0.6 Report

any discrepancy observed during the operation and calibration of the instrument to

Section

In charge of his representative for corrective and preventative action as per Sop No. XYZ/CQA/SOP-030, CAPA.

5.0.7 Section Charge or his representative will take the necessary action and report the same to Manager-Quality Assurance.

5.0.8 Affix the “Out of Order” label on the instrument as per SOP No. XYZ/CQA/SOP-006, Labelling Policy.

Cleaning of AHU and Ventilation filters

This SOP applies to the Air handling unit in the production dept the quality control department and the ventilation filters of the service floor.

Before opening the AHU push the starter button in

off condition Open the filter door of the AHU.

Remove the filter from the inside.

Take the filter to the washing room on the service

floor.

Spray raw water and soap water on filters.

Rub it with a nylon brush.

Spray raw water again to remove the soap.

Pass compressed air on both the sides of

filter.

Allow it to dry.

Fix the filter in AHU.

Close the door of AHU.

Clean the cabin of AHU from the inside with a wet

cloth using soap and water. Check the ‘V’ belt, motor pulley, and fan pulley of the AHU

unit.

6.0 ABBREVIATION

XYZ XYZ Limited

SOP Standard Operating Procedure

CQA Corporate

Quality Assurance

A.H.U. Air Handling Unit

CAPA Corrective And Preventative Action