A hammer mill is a machine that is used to crush materials with the use of hammers. Many people use hammers to crush materials, such as stone, into powder. The material produced by a hammer mill is called a hammer meal.

Hammer mills are very useful in mining, mining exploration, and agriculture. They are also used in many manufacturing processes such as cement, stone processing, metallurgy, and paper-making.

{tocify} $title={Table of Contents}

Principle of Hammer Mill

Size reduction is achieved by impact and attrition. Therefore, a hammer mill is an important invention that will help us process many materials and create many useful items.

A hammer mill is a device that is used to crush material into smaller pieces with the use of hammers. The main parts of a hammer mill include a path, hammers, mechanism, and auger. A path is a horizontal or vertical channel that holds the material being crushed. Hanging hammers are used to crush the material inside the path and create a hammer meal. Also, pinions and gears help to rotate the hammers as they pound the material into powder.

Construction

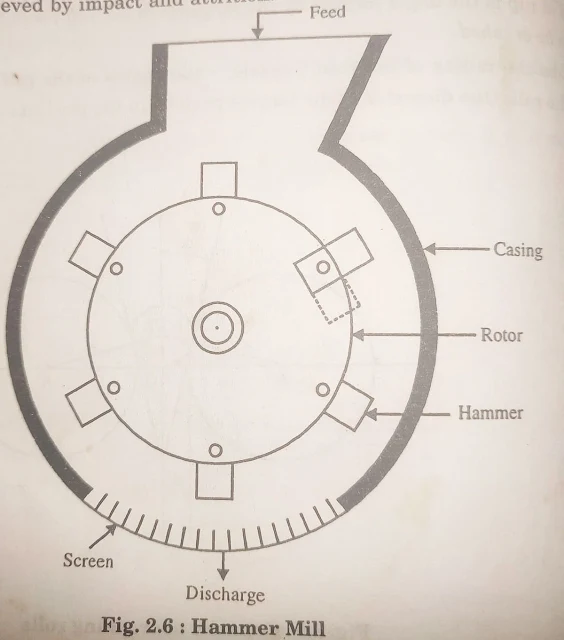

The hammer mill consists essentially of a high-speed rotor turning inside a cylindrical casing. The rotor is mounted on a shaft which is usually horizontal. The swing hammers are pinned to a rotor disk. The hammers may be straight bars of metal with plain or enlarged ends. In this mill, the particles are broken by the sets of swing hammers. The product falls through a grate or screen which forms the lower portion of the casing.

Several rotor disks each carrying four to eight swing hammers are often mounted on a single shaft. The rotor disk diameter ranges from 150 mm to 250 mm. As the hammers are hinged, the presence of any hard material does not cause damage to the equipment. The hammers are readily replaced when they are worn out.

Working Principle

The material to be crushed is fed to a mill from the top. It is thrown out centrifugal and crushed by being beaten between the hammer bars, or against breaker plates fixed around the periphery of the cylindrical casing. The material is beaten by the hammers until it is small enough to fall through a screen (that covers the discharge opening)

Intermediate hammer mills give a product 25 mm to 20 mesh in particle size. In a hammer Mill employed for fine production, the peripheral speed of the hammer tips may reach 112 m/s and they reduce 0.1 to 15 t/h of materials to sizes finer than 200 mesh.

Hammer mills are employed for tough fibrous solids like bark or leather, steel turnings, hard rock, sticky clay, etc. They are limited to soft materials for a fine reduction.

Advantages

- Hammer mills are metal working units that are used for processing materials.

- They are very efficient and have many advantages.

- Most manufacturing industries use hammer mills to process metal, which makes them very common.

- They're easy to use and can save you time, energy, and cost.

- You can recycle the hammers from your hammer mill for new uses and make it environmentally friendly.

- The inventors of hammer mills found a way to reuse and recycle materials.

- Hammer mills are used in industries such as steel, coal, aluminum, and cement manufacturing.

- They're especially useful in manufacturing where large quantities of materials need to be processed.

- Hammer mills can reduce the amount of energy needed to process materials.

Revolving of Hammer Mills/Tumbling Mills

A cylindrical shell slowly rotating on a horizontal axis and charged with a grinding medium to about half its volume forms a revolving Mills / Tumbling mill. The shell is usually made of steel and lined with abrasion-resistant materials such as manganese steel, ceramic, or rubber. The grinding medium is usually made of flint, ceramic, or metal. Ball, pebble, tube in that it is short in length; the length is approximately equal to its diameter.

The grinding medium more commonly used in the ball mill is steel balls. The tube mill is usually long in comparison with its diameter, the length being twice the diameter or more. It employs smaller balls and produces a finer product. The rod mill employs metal rods as a grinding medium and delivers more uniform products than any other revolving Mill.

In a ball mill or pebble mill, much of the reduction is affected by impact while in a rod mill, much of the reduction is affected by rolling, compression, and attention. The ball mill and pebble mill are very easy to operate and versatile in use.

Take these Notes is, Orginal Sources: Unit Operations-II, KA Gavhane