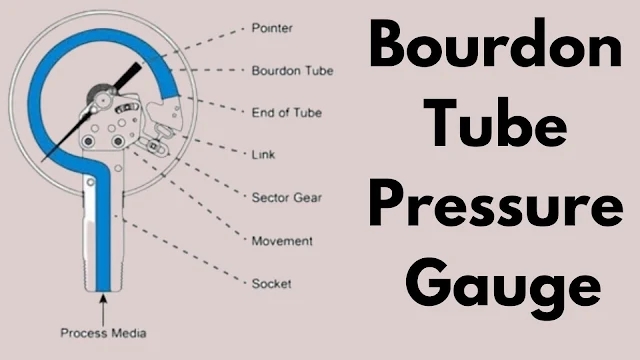

Bourdon tube pressure gauge is the most commonly used pressure gauge, it covers the range from 0 - 15 to 0 - 100000 Psi. It consists of the following written parts. Bourdon tubes come in different types and uses.

1. Bourdon Tube

It is a tube with a round cross-section that changes its curvature according to the pressure applied inside it, its free end is connected to a link. When a pointer is attached, it is made of any metal or mixed metal, so that it can bear the pressure and there is no effect of corrosion.

{tocify} $title={Table of Contents}

2. Link

Link is the device that is attached to the free end of the bourdon tube using sector and pinion. When bourdon tubes work, the links work too.

3. Sector & Pinion

Pinion has a pointer and is connected to the sector with the help of pinion gear. When the sector moves with the link, the pinion also moves with the pointer and the reading is obtained on the scale.

4. Pointer

It is a metal rod that displays the value of the measured quantity on a scale.

5. Scale

There is a scale in this pressure gauge which is made of paper, there are many marks on this paper.

6. Case

The entire instrument fits inside the case, it is made of milled steel, bronze, cast iron or aluminum.

7. Pointer Stop

It is in the form of a pin or raised surface.

8. Transparent Cover

It is made of ordinary glass or acrylic glass of uniform thickness.

Working Principle

The open end of the bourdon tube is connected to the pressure source, when the pressure acts on the bourdon tube, the tube tries to be in a state line, as a result of which there is a displacement at the closed end of the tube, this displacement is caused by link sector gear and pinion indicating is converted to the rotation of the pointer. Which rotates on the gauge dial. There is a scale on the dial with the help of which the pressure is read.

Advantages and Disadvantages

Advantages

1. Low cost and simple construction.

2. Time-tested applications.

3. Heigh accuracy especially about cost.

4. A adaptability to transducer design for the electric instruments.

5. Availability in a wide variety of ranges including very high ranges.

Disadvantage

1. Low spring gradient.

2. Susceptibility to shock and vibration.

3. Susceptibility to hysteresis.

Uses

Bourdon tubes several important uses in various industries and applications:

1. Bourdon tubes are commonly found in pressure gauges used to measure and display the pressure of gases or fluids in a wide range of applications, such as automotive, industrial, and HVAC systems.

2. They are used in industrial processes to monitor and control pressure in systems like chemical processing, oil and gas production, and manufacturing.

3. Bourdon tubes can be found in hydraulic pressure gauges and systems to ensure the proper functioning and safety of hydraulic machinery and equipment.

4. In steam boilers, Bourdon tubes are used to measure and control steam pressure to maintain safe and efficient operation.

5. Bourdon tubes are employed in aircraft instrumentation to measure various pressures, including cabin pressure, hydraulic system pressure, and fuel pressure.

6. Some medical equipment, like blood pressure monitors, use Bourdon tubes to measure and display blood pressure accurately.

7. They are utilized in marine instrumentation to monitor and control pressures in systems onboard ships and submarines.

8. Bourdon tube pressure gauges are used in heating, ventilation, and air conditioning systems to ensure proper pressure levels for efficient operation.

9. Scientific instruments and laboratory equipment may use Bourdon tubes to measure and control pressures in experiments and research.

10. In the automotive industry, Bourdon tubes can be used in various applications, including tire pressure monitoring systems and engine pressure measurement.

Bourdon tubes play a crucial role in monitoring and controlling pressure in a wide range of mechanical, industrial, and scientific systems, contributing to safety, efficiency, and accurate measurement.

Types of Bourdon Tube

Bourdon tubes come in different types and configurations to suit various applications and pressure measurement needs.

1. C-Type Bourdon Tube

This is the most common type, featuring a curved tube that tends to straighten when pressurized. It is suitable for general pressure measurement applications.

2. Spiral Bourdon Tube

Instead of a simple curve, the spiral Bourdon tube has a helical or spiral shape. This design provides greater sensitivity to pressure changes and is often used in precision pressure gauges.

3. Helical Bourdon Tube

Similar to the spiral tube, the helical Bourdon tube is coiled in a helix shape. It is used in applications requiring high pressure measurement accuracy.

4. Arc Bourdon Tube

Arc Bourdon tubes have a partial curve, making them suitable for applications with limited space or where the gauge face needs to be flat.

5. Spiral Wound Bourdon Tube

This type consists of a spiral-wound strip of metal, offering excellent sensitivity and resistance to shock and vibration. It's used in applications with dynamic pressure changes.

6. Coiled Bourdon Tube

Coiled Bourdon tubes are used in specialized applications where compact design and resistance to high pressures are required.

7. Diaphragm Bourdon Tube

In this design, the Bourdon tube is integrated into a diaphragm, allowing it to measure differential pressure across the diaphragm. It's used in applications like differential pressure gauges.

8. Capsule Bourdon Tube

Capsule Bourdon tubes consist of two curved diaphragms sealed together. They are used for measuring very low pressures and vacuum.

9. Duplex Bourdon Tube

This type combines two Bourdon tubes in one instrument to measure both pressure and temperature simultaneously. It's used in applications where pressure and temperature are critical factors.

The choice of Bourdon tube type depends on factors such as the pressure range, accuracy requirements, environmental conditions, and space constraints of the specific application.