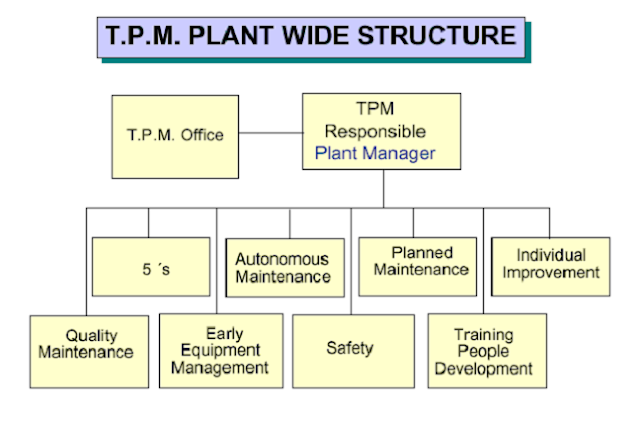

TPM starts with 5S. Problems cannot be clearly seen when the workplace is unorganized. Cleaning and organizing the workplace helps the team to uncover problems. Making problems visible is the first step toward improvement. Organization Structure for TPM Implementation

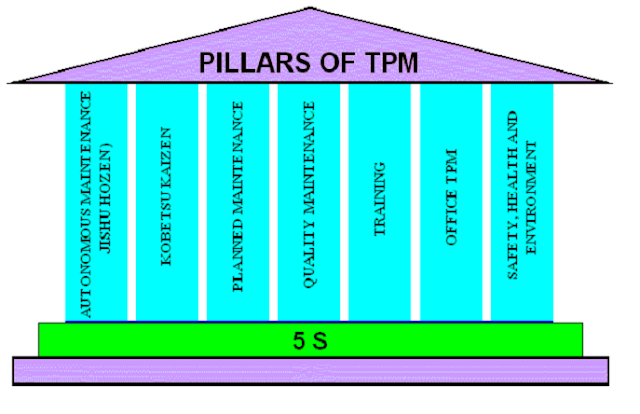

Pillars of TPM

PILLAR 1–5S:

Japanese Term English Translation.

Equivalent 'S' term Seiri Organisation Sort.

Seiton Tidiness Systematise.

Seiso Cleaning Sweep.

Seiketsu Standardisation Standardise.

Shitsuke Discipline Self-Discipline.

{tocify} $title={Table of Contents}

SEIRI (Sort Out)

This means sorting and organizing the items as critical, important, frequently used items, useless, or items that are not needed as of now. Unwanted items can be salvaged. Critical items should be kept for use nearby and items that are not used shortly should be stored in someplace. For this step, the worth of the item should be decided based on utility and not cost. As a result of this step, the search time is reduced.

Priority Frequency of Us How to use

Low Less than once per year, Once per year Throw away, Store away from the workplace

Average At least 2/6 months, Once per month, Once per week Store together but offline

High Once Per Day Locate at the workplace

SEATON (Organise)

The concept here is that "Each item has a place and only one place". The items should be placed back after usage at the same place. To identify items easily, nameplates and colored tags have to be used. Vertical racks can be used for this purpose, and heavy items occupy the bottom position in the racks.

SEISO (Shine the workplace)

This involves cleaning the workplace free of burrs, grease, oil, waste, scrap, etc. No loosely hanging wires or oil leakage from machines.

SEIKETSU (Standardization)

Employees have to discuss together and decide on standards for keeping the workplace / Machines/pathways neat and clean. These standards are implemented for the whole organization and are tested / Inspected randomly.

SHITSUKE (Self-discipline)

Considering 5S as a way of life brings about self-discipline among the employees of the organization. This includes wearing badges, following work procedures, punctuality, dedication to the organization, etc.

PILLAR 2-JISHU HOZEN ( Autonomous maintenance ) :

This pillar is geared towards developing operators to be able to take care of small maintenance tasks, thus freeing up skilled maintenance people to spend time on more value-added activities and technical repairs. The operators are responsible for the upkeep of their equipment to prevent it from deteriorating.

Policy:

⦁ Uninterrupted operation of equipment.

⦁ Flexible operators to operate and maintain other equipment.

⦁ Eliminating the defects at the source through active employee participation.

⦁ A stepwise implementation of JH activities.

JISHU HOZEN Targets:

⦁ Prevent the occurrence of 1A / 1B because of JH.

⦁ Reduce oil consumption by 50%

⦁ Reduce process time by 50%

⦁ Increase use of JH by 50%

Steps in JISHU HOZEN:

⦁ Preparation of employees.

⦁ Initial cleanup of machines.

⦁ Take countermeasures

⦁ Fix tentative JH standards

⦁ General inspection

⦁ Autonomous inspection

⦁ Standardization and

⦁ Autonomous management.

Each of the above-mentioned steps is discussed in detail below.

⦁ Train the Employees: Educate the employees about TPM, Its advantages, JH advantages, and Steps in JH. Educate the employees about abnormalities in types of equipment.

⦁ Initial cleanup of machines :

⦁ The supervisor and technician should discuss and set a date for implementing step1

⦁ Arrange all items needed for cleaning

⦁ On the arranged date, employees should clean the equipment completely with the help of the maintenance department.

⦁ Dust, stains, oils, and grease have to be removed.

⦁ Following are the things that have to be taken care of while cleaning. They are Oil leakage, loose wires, unfastened nuts and bolts, and worn-out parts.

⦁ After clean up problems are categorized and suitably tagged. A white tag is a place where problems can be solved by operators. A pink tag is placed where the aid of the maintenance department is needed.

⦁ Contents of the tag are transferred to a register.

⦁ Make note of inaccessible areas.

⦁ Finally, close the open parts of the machine and run the machine.

⦁ Counter Measures :

⦁ Inaccessible regions had to be reached easily. E.g. If there are any screws to open a flywheel door, a hinged door can be used. Instead of opening a door for inspecting the machine, acrylic sheets can be used.

⦁ To prevent the work out of machine parts necessary action must be taken.

⦁ Machine parts should be modified to prevent the accumulation of dirt and dust.

⦁ Tentative Standard :

⦁ JH schedule has to be made and followed strictly.

⦁ The schedule should be made regarding cleaning, inspection, and lubrication and it also should include details like when what, and how.

⦁ General Inspection:

⦁ The employees are trained in disciplines like Pneumatics, electrical, hydraulics, lubricant and coolant, drives, bolts, nuts, and Safety.

⦁ This is necessary to improve the technical skills of employees and to use inspection manuals correctly.

⦁ After acquiring this new knowledge the employees should share this with others.

⦁ By acquiring this new technical knowledge, the operators are now well aware of machine parts.

⦁ Autonomous Inspection:

⦁ New methods of cleaning and lubricating are used.

⦁ Each employee prepares his own autonomous chart/schedule in consultation with the supervisor.

⦁ Parts that have never been given any problem or parts that don't need any inspection are removed from the list permanently based on experience.

⦁ Including good-quality machine parts. This avoids defects due to poor JH.

⦁ An inspection that is made in preventive maintenance is included in JH.

⦁ The frequency of cleanup and inspection is reduced based on experience.

⦁ Standardization:

⦁ Up to the previous stem, only the machinery/equipment was the concentration. However, in this step, the surroundings of the machinery are organized. Necessary items should be organized, such that there is no searching and searching time is reduced.

⦁ The work environment is modified such that there is no difficulty in getting any item.

⦁ Everybody should follow the work instructions strictly.

⦁ Necessary spares for types of equipment are planned and procured.

Autonomous Management:

- OEE OPE and other TPM targets must be achieved by continuous improvement through Kaizen.

- PDCA ( Plan, Do, Check, and Act ) cycle must be implemented for Kaizen.

PILLAR 3 - KAIZEN

"Kai" means change, and "Zen" means good ( for the better ). Basically, kaizen is for small improvements but is carried out continually and involves all people in the organization. Kaizen is the opposite of big spectacular innovations. Kaizen requires no or little investment. The principle behind is that "a very large number of small improvements are more effective in an organizational environment than a few improvements of large value. This pillar is aimed at reducing losses in the workplace that affect our efficiencies. By using a detailed and thorough procedure we eliminate losses in a systematic method using various Kaizen tools. These activities are not limited to production areas and can be implemented in administrative areas as well.

Kaizen Policy:

- Practice concepts of zero losses in every sphere of activity. relentless pursuit to achieve cost reduction targets in all resources.

- Relentless pursuit to improve overall plant equipment effectiveness.

- Extensive use of PM analysis as a tool for eliminating losses.

- The focus of easy handling of operators.

Kaizen Target:

Achieve and sustain zero losses to minor stops, measurement and adjustments, defects, and unavoidable downtimes. It also aims to achieve a 30% manufacturing cost reduction.

Tools used in Kaizen:

- PM analysis.

- Why - Why analysis.

- Summary of losses.

- Kaizen register.

- Kaizen summary sheet.

The objective of TPM is the maximization of equipment effectiveness. TPM aims at maximization of machine utilization and not merely machine availability maximization. As one of the pillars of TPM activities, Kaizen pursues efficient equipment, operator, and material and energy utilization, which is extreme productivity and aims at achieving substantial effects. Kaizen activities try to thoroughly eliminate 16 major losses.

16 Major losses in an organization:

Loss Category

- Failure losses - Breakdown loss.

- Setup/adjustment losses.

- Cutting blade loss.

- Startup loss.

- Minor stoppage / Idling loss.

- Speed loss - operating at low speeds.

- Defect/rework loss.

- Scheduled downtime loss.

- Losses that impede equipment efficiency.

- Management loss.

- Operating motion loss.

- Line organization loss.

- Logistic loss.

- Measurement and adjustment loss.

- Losses that impede human work efficiency.

- Energy loss.

- Die, jig, and tool breakage loss.

- Yield loss. Loses that impede the effective use of production resources.

Classification of Losses:

- Aspect Sporadic Loss Chronic Loss.

- Causation Causes for this failure can be easily traced. The cause-effect relationship is simple to trace. This loss cannot be easily identified and solved. Even if various countermeasures are applied.

- Remedy Easy to establish a remedial measure This type of loss is caused because of hidden defects in machines, equipment, and methods.

- Impact / Loss A single loss can be costly.

- A single cause is rare - a combination of causes trends to be a rule.

- Frequency of occurrence The frequency of occurrence is low and occasional. The frequency of loss is higher.

- Corrective action Usually the line personnel in the production can attend to this problem. Specialists in process engineering, quality assurance, and maintenance people are required.

PILLAR 4 - PLANNED MAINTENANCE

It is aimed to have trouble-free machines and types of equipment producing defect-free products for total customer satisfaction. This breaks maintenance down into 4 "families" or groups which was defined earlier.

- Preventive Maintenance.

- Breakdown Maintenance.

- Corrective Maintenance.

- Maintenance Prevention.

With Planned Maintenance, we evolve our efforts from a reactive to a proactive method and use trained maintenance staff to help train the operators to better maintain their equipment.

Policy:

- Achieve and sustain the availability of machines.

- Optimum maintenance cost.

- Reduces spare inventory.

- Improve reliability and maintainability of machines.

Target:

- Zero equipment failure and breakdown.

- Improve reliability and maintainability by 50 %.

- Reduce maintenance costs by 20 %.

- Ensure availability of spares all the time.

Six steps in Planned maintenance

- Equipment evaluation and recording present status.

- Restore deterioration and improve weakness.

- Building up an information management system.

- Prepare a time-based information system, select equipment, parts, and members, and map out a plan.

- Prepare a predictive maintenance system by introducing equipment diagnostic techniques.

- Evaluation of planned maintenance.

PILLAR 5 - QUALITY MAINTENANCE

It is aimed toward customer delight through the highest quality through defect-free manufacturing. Focus is on systematically eliminating non-conformances, much like Focused Improvement. We gain an understanding of what parts of the equipment affect product quality and begin to eliminate current quality concerns, then move to potential quality concerns. The transition is from reactive to proactive (Quality Control to Quality Assurance).

QM activities are to set equipment conditions that preclude quality defects, based on the basic concept of maintaining perfect equipment to maintain the perfect quality of products. The condition is checked and measured in time series to very that measure values are within standard values to prevent defects. The transition of measured values is watched to predict the possibilities of defects occurring and to take countermeasures beforehand.

Policy:

- Defect-free conditions and control of equipment.

- QM activities to support quality assurance.

- The focus is on the prevention of defects at the source.

- Focus on poka-yoke. (foolproof system ).

- In-line detection and segregation of defects.

- Effective implementation of operator quality assurance.

Target:

- Achieve and sustain customer complaints at zero.

- Reduce in-process defects by 50 %.

- Reduce the cost of quality by 50 %.

Data requirements

Quality defects are classified as customer-end defects and in-house defects. For customer-end data, we have to get data on

- Customer end-line rejection.

- Field complaints.

In-house, data include data related to products and data related to process

Data related to the product

- Product-wise defects.

- The severity of the defect and its contribution - major/minor.

- Location of the defect concerning the layout.

- The magnitude and frequency of its occurrence at each stage of measurement.

- Occurrence trends at the beginning and the end of each production/process/change. (Like pattern change, ladle/furnace lining, etc.).

- Occurrence trend concerning the restoration of breakdown/modifications/periodical replacement of quality components.

Data related to processes:

- The operating condition for individual sub-process related to men, method, material, and machine.

- The standard settings/conditions of the sub-process.

- The actual record of the settings/conditions during the defect occurrence.

PILLAR 6 - TRAINING

It is aimed to have multi-skilled revitalized employees whose morale is high and who are eager to come to work and perform all required functions effectively and independently. Education is given to operators to upgrade their skills. It is not sufficient to know only "Know-How" they should also learn "Know-why". Through experience, they gain, "Know-How" to overcome a problem and what to be done. This they do without knowing the root cause of the problem and why they are doing so. Hence it becomes necessary to train them to know "Know why". The employees should be trained to achieve the four phases of skill. The goal is to create a factory full of experts. The different phases of skills are

Phase 1: Do not know.

Phase 2: Know the theory but cannot do it.

Phase 3: Can do but cannot teach

Phase 4: Can do and also teach.

Policy:

- Focus on improvement of knowledge, skills, and techniques.

- Creating a training environment for self-learning based on felt needs.

- Training curriculum/tools/assessment etc conducive to employee revitalization.

- Training to remove employee fatigue and make work enjoyable.

Target:

- Achieve and sustain downtime due to want men at zero on critical machines.

- Achieve and sustain zero losses due to lack of knowledge/skills/techniques.

- Aim for 100 % participation in the suggestion scheme.

Steps in Educating and Training Activities

- Setting policies and priorities and checking the present status of education and training.

- Establish a training system for operation and maintenance skill up-gradation.

- Training the employees to upgrade their operation and maintenance skills.

- Preparation of training calendar.

- Kick-off of the system for training.

- Evaluation of activities and study of future approach.

PILLAR 7 - OFFICE TPM

Office TPM should be started after activating four other pillars of TPM (JH, KK, QM, PM). Office TPM must be followed to improve productivity, and efficiency in the administrative functions and to identify and eliminate losses. This includes analyzing processes and procedures toward increased office automation. Office TPM addresses twelve major losses. They are

- Processing loss.

- Cost loss including in areas such as procurement, accounts, marketing, sales leading to high inventories.

- Communication loss.

- Idle loss.

- Set-up loss.

- Accuracy loss.

- Office equipment breakdown.

- Communication channel breakdown, telephone, and fax lines.

- Time spent on retrieval of information.

- Non-availability of correct online stock status.

- Customer complaints due to logistics.

- Expenses on emergency dispatches/purchases.

How to start office TPM?

A senior person from one of the support functions e.g. Head of Finance, MIS, Purchase, etc should be heading the sub-committee. Members representing all support functions and people from Production & Quality should be included in the subcommittee. TPM coordinates plans and guides the subcommittee.

- Providing awareness about office TPM to all support departments.

- Helping them to identify P, Q, C, D, S, and M in each function about plant performance.

- Identify the scope for improvement in each function.

- Collect relevant data.

- Help them to solve problems in their circles.

- Make up an activity board where progress is monitored on both sides - results and actions along with Kaizens.

- Fan out to cover all employees and circles in all functions.

Kotetsu Kaizen topics for Office TPM

- Inventory reduction.

- Lead time reduction of critical processes.

- Motion & space losses.

- Retrieval time reduction.

- Equalizing the workload.

- Improving the office efficiency by eliminating the time loss on retrieval of information, by achieving zero breakdowns of office equipment like telephone and fax lines.

Office TPM and its Benefits

- Involvement of all people in support functions for focusing on better plant performance.

- Better utilized work area.

- Reduce repetitive work.

- Reduced inventory levels in all parts of the supply chain.

- Reduced administrative costs.

- Reduced inventory carrying cost.

- Reduction in the number of files.

- Reduction of overhead costs (to include the cost of non-production/non-capital equipment).

- Productivity of people in support functions.

- Reduction in breakdown of office equipment.

- Reduction of customer complaints due to logistics.

- Reduction in expenses due to emergency dispatches/purchases.

- Reduced manpower.

- Clean and pleasant work environment.

PQCDSM in Office TPM :

P - Production output lost due to wanting of material, Manpower Productivity, Production output lost due to wanting of tools.

Q - Mistakes in preparation of cheques, bills, invoices, payroll, Customer returns/warranty attributable to BOPs, Rejection/rework in BOPs/job work, Office area rework.

C- Buying cost/unit produced, Cost of logistics - inbound/outbound, Cost of carrying inventory, Cost of communication, Demurrage costs.

D - Logistics losses (Delay in loading/unloading)

- Delay in delivery due to any of the support functions

- Delay in payments to suppliers

- Delay in information

S - Safety in material handling/stores/logistics, Safety of soft and hard data.

M - Number of kaizens in office areas.

How office TPM supports plant TPM :

Office TPM supports the plant, initially in doing Jishu Hozen of the machines (after getting training of Jishu Hozen), as in Jishu Hozen at the Initial stages machines are more and manpower is less, so the help of commercial departments can be taken, for this Office TPM can eliminate the lodes online for no material and logistics.

Extension of office TPM to suppliers and distributors :

This is essential, but only after we have done as much as possible internally. With suppliers, it will lead to on-time delivery, improved 'in-coming' quality, and cost reduction. With distributors, it will lead to accurate demand generation, improved secondary distribution, and a reduction in damages during storage and handling. In any case, we will have to teach them based on our experience and practice and highlight gaps in the system that affect both sides. In this case, some of the larger companies, have started to support clusters of suppliers.

PILLAR 8 - SAFETY, HEALTH, AND ENVIRONMENT

Target :

- Zero accident.

- Zero health damage.

- Zero fires.

In this area, the focus is on creating a safe workplace and a surrounding area that is not damaged by our processes or procedures. This pillar will play an active role in each of the other pillars regularly.