Sop for Industries waste handling, disposal, and storage in a chemical industry.

1.0 OBJECTIVE

1.1 To lay down the procedure for Disposal of Waste.

2.0 SCOPE

2.1 This procedure applies to the Store of Units.

3.0 RESPONSIBILITIES

3.1 Store officer to follow the SOP.

3.2 Head – Store for implementation of SOP.

4.0 Procedure

4.1 Type of chemical industries wastage

4.1.1 Wrapper

4.1.2 Stiffener

4.1.3 CLD

4.1.4 Soap Scrap (can't use)

4.1.5 Core of

wrapper & stiffener

4.1.6 Empty

Chemical bags

4.1.7 Empty chemical containers

4.1.8 Lab waste

4.1.9 Toilet waste

4.1.10 Drinking water point waste

4.1.11 Canteen Waste

4.1.12 Floor cleaning waste

4.1.13 Glycerin and perfume drum washing waste

4.2 DISPOSAL OF WRAPPER & STIFFENER WASTAGE

4.2.1 Check and ensure that wrapper & stiffener scrap bags are in their respective areas in every shift.

4.2.2 Take a shift-wise wrapper and stiffener scrap bags weigh individual bags on the weigh scale and record the same in the logbook.

4.2.3 Transfer

these bags to the scrap yard and put these bags into the correct location in the

scrap yard.

4.2.4 Sell these scraps after shredding.

4.3 DISPOSAL OF CLD WASTAGE

4.3.1 Check and ensure that CLD scrap is kept

in the respective area in every shift.

4.3.2 Destroy the CLD Transfer these bags to scrap yards & sell them.

4.4 DISPOSAL OF SOAP SCRAP

4.4.1 Soap scrap which cannot be reused, is collected in a designated container outside the plant.

4.4.2 Sell these scraps.

4.5 DISPOSAL OF EMPTY CHEMICAL BAGS

4.5.1 Transfer these bags to scrap yards.

4.5.2 Sell these scraps after destroying them.

4.6 DISPOSAL OF EMPTY RAW MATERIAL CONTAINERS

4.6.1 Transfer these containers to the scrap yard.

4.6.2 Sell these scraps.

4.7 DISPOSAL OF LAB WASTE

4.7.1 Lab chemical waste, water waste, and microbiological waste should be checked. Concentrated chemicals should not be discarded, dilute them with water and then discard them.

4.7.2 Microbiological waste should be wrapped in a labeled poly bag. Put the microbiological waste into the ETP plant. And wastewater shall automatically pass to the ETP plant.

4.8 DISPOSAL

OF TOILET WASTE AND DRINKING WATER POINT WASTE

4.8.1 Toilet waste & drinking water point water waste shall automatically drain into the ETP plant.

4.9 DISPOSAL

OF CANTEEN WASTE

4.9.1 Canteen waste shall also drain into the ETP plant.

4.10 DISPOSAL

OF FLOOR CLEANING WASTE

4.10.1 After floor cleaning of all areas, the waste should be dropped at the place from where the waste automatically passes into the ETP plant.

4.11 DISPOSAL

OF GLYCERINE & PERFUME DRUM WASHING WASTE

4.11.1 All used drums of glycerin & perfume should be washed thoroughly and drained the waste into the pit which passes the waste directly into the ETP plant.

5.0 ABBREVIATIONS

5.1 SOP: Standard Operating Procedure

5.2 CLD: Corrugated

Load Box

5.3 ETP: Effluent Treatment Plant

6.0 REFERENCE: NIL

Waste management procedure

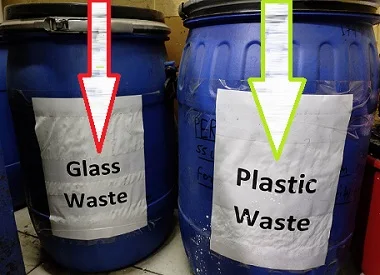

1. Collect all the Waste in all the Departments in Waste Bins as under:

Green – Biodegradable waste (Like paper, jute, metals, etc.

Yellow – Non - Biodegradable waste (Like Plastic, rubber, etc.)

Red - Hazardous waste ( Like Chemical Scrubbing)

2. For a collection of used oil, place a drum in a tray near the oil exit point.

3. During the discharge, take care that no oil is spilled over to land. Any spillage into the tray should be collected and put into the drum.

4. After the complete discharge of oil, close the drum with a cap tightly hand over to the scrap yard from time to time, and get it entered in their stock record.

5. After the complete discharge of oil, close the drum with a cap tightly hand it over to the scrap yard from time to time, and get it entered in their stock record.

6. The collected rags are to be handed over to the store department and over to the scrapyard from time to time and entered into their stock record.

5. After the complete discharge of oil, close the drum with a cap tightly hand it over to the scrap yard from time to time, and get it entered in their stock record.

6. The collected rags are to be handed over to the store department for SSWML.

7. The Stores Department shall dispose of used batteries by returning them.

Hazard Analysis Critical Control Points (HACCP) | 7 Principles of HACCP

Procedure for disposal of scrap material

1.0 OBJECTIVE

1.1 To lay down the procedure for Handling Category "A", "B", and "C" non-conforming products.

2.0 SCOPE

2.1 This procedure applies to the Production of XYZ.

3.0 RESPONSIBILITIES

3.1 Shift Officer & online QA to follow the SOP.

3.2 Head – Production & QA for compliance of SOP.

SOP of HOT AIR OVEN

4.0 PROCEDURE

4.1 Category "A" Non-conforming product.

4.1.1 The following are to be collected in Green bags:

4.1.1. Material wastage during machine adjustments.

4. 1.2.1 All improperly wrapped tablets are collected in a yellow-colored tray.

4.1. 2.2 The tablets are to be de-wrapped as soon as they are recycled conveyors.

4.1.2.3 If De-wrapped tablets are becoming hard to collect in green bags and recycle via mixture.

4.1.2.4 In the case of addition through the mixture, not more than 5% should be added per batch.

4.1.2.5 Care should be taken while handling the de-wrapped tablets to ensure that no foreign matter is contaminated.

4.2 Category "B" Non-conforming product.

4.2.1 The following are to be collected in white Bags:

4.2.1.1 Floor sweeping and those fallen on the floor.

4.2.1.2 Those rejections for foreign matter ingress.

4.2.2 Handling procedure of category "B" non-conforming product

4.2.2.1 Such tablets should be collected in white-colored bags segregated for rework

4.2.3 Rework Process

4.2.3.1 Take some scrap to be reworked in the SS trolley, and scratch out the dust or foreign matter with the scrapping tool.

5.0 ABBREVIATIONS

SOP: Standard Operating ProcedureQA: Quality Assurance